|

Galileo series software

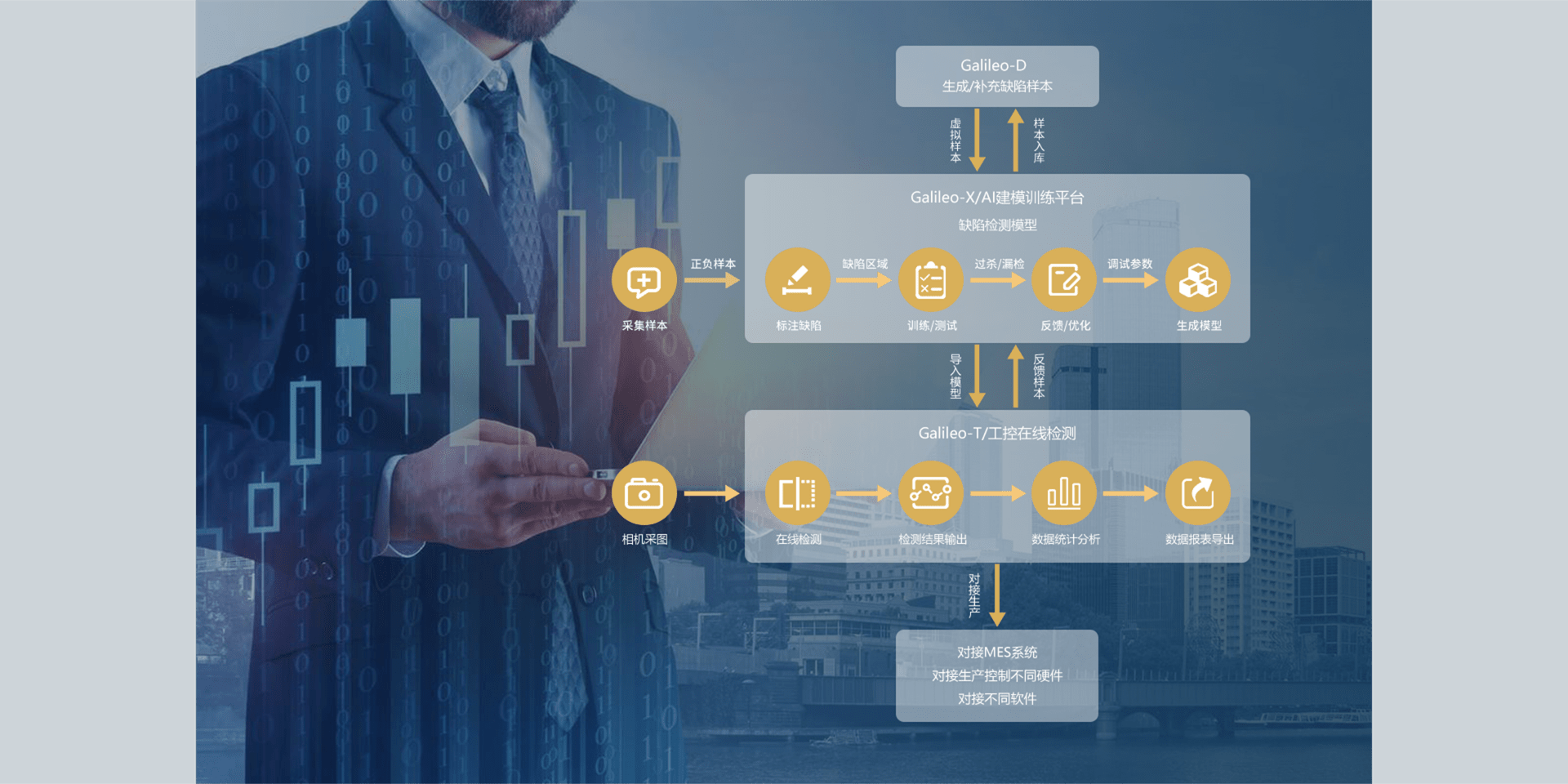

Based on the application scenarios of fast deep learning technology in industrial vision and industrial defect detection, we launched "Galileo" series of software products.This series of products will be "AI deep learning algorithm, model training, model testing, online detection and analysis, data analysis report, automatic generation of defects, cloud deep learning service, AI customized algorithm" and other one-stop implementation.Different functional modules and different products can be selected according to the different needs of customers' actual use scenarios |

|

-

Galileo-X

Deep learning system

-

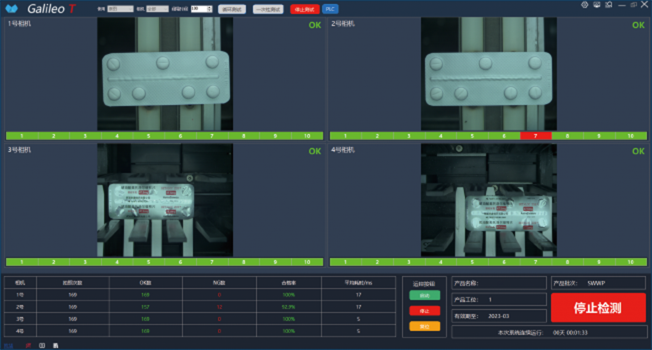

Galileo-T

Online detection system

-

Galileo-T

Big data aided decision making system

-

Productiz covenant-lite

Designed for local production enterprises, very simple production line workers maintenance interface

-

High efficiency

Fast modeling and labeling, saving 80% of the time;Customization greatly improves the detection speed

-

High speed neural network

Self-research core technology,optimized neural network,model accelerates over 30~50 times

-

High accuracy

Through addition and feedback training, the detection accuracy is close to 100%

-

Whole process inspection

Constructing four whole process testing system, the industrial application is more extensive

-

Support for complex images

Sensitive detection under complexity background, beyond the existing traditional image analysis, detection technology

-

Cross-platform Compatibility

The new framework of deep learning can be docked and transplanted to any software and hardware platform

-

Visual report

Support the output of custom, visual test and detection reports

-

Over 2 billion sample bases

More than 2 billion samples of industrial production defects

-

Setting standards flexibly

Adjust positive and negative samples according to production requirements, conduct optimization training

-

Online quality inspection

Multi-equipment on-line quality inspection big data analysis, to provide reliable decision aid for industrial production

-

MES System

Docking MES system

2.5D / 3D Phone Cover Glass

Surface detection

![]() Speed:≤ 2.3s/pc

Speed:≤ 2.3s/pc

![]() Result:Loss ≤ 2.5% | Fault ≤ 10%

Result:Loss ≤ 2.5% | Fault ≤ 10%

![]() Type:Smudge, hair, dust spot, scratch, edge collapse, bump, deep scratch......

Type:Smudge, hair, dust spot, scratch, edge collapse, bump, deep scratch......

-

master map

-

result

Metallized Ceramics

Surface detection

![]() Speed:≤ 100ms/pc

Speed:≤ 100ms/pc

![]() Result:Loss ≤ 0.3% | Fault ≤ 1%

Result:Loss ≤ 0.3% | Fault ≤ 1%

![]() Type:Scratches, chipped edges, smudges, cracks, scratches, missing......

Type:Scratches, chipped edges, smudges, cracks, scratches, missing......

-

master map

-

result

Metallic Part

Surface detection

![]() Speed:≤ 500ms/pc

Speed:≤ 500ms/pc

![]() Result:Loss ≤ 0.1% | Fault ≤ 5%

Result:Loss ≤ 0.1% | Fault ≤ 5%

![]() Type:Smudge, bright mark, scratch, spot, mold, knife grain, notch......

Type:Smudge, bright mark, scratch, spot, mold, knife grain, notch......

-

master map

-

result

Industrial character recognition

Surface detection

![]() Speed:≤ 120ms/pc

Speed:≤ 120ms/pc

![]() Result:Precision rate ≥ 99.99%

Result:Precision rate ≥ 99.99%

-

master map

-

result

Electronic Components

Surface detection

![]() Speed:≤ 2ms/pc

Speed:≤ 2ms/pc

![]() Result:Loss ≤ 0.01% | Fault ≤ 1%

Result:Loss ≤ 0.01% | Fault ≤ 1%

![]() Type:Magnetic leakage,bubbles,cracking,deformation,black,crack,crescent,trachoma,indentation......

Type:Magnetic leakage,bubbles,cracking,deformation,black,crack,crescent,trachoma,indentation......

-

master map

-

result

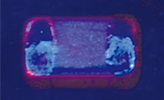

Pouch power cell

Surface detection

![]() Speed:≤ 5s/pc

Speed:≤ 5s/pc

![]() Result:Loss ≤ 0.1%(serious defects is 0) | Fault ≤ 5%

Result:Loss ≤ 0.1%(serious defects is 0) | Fault ≤ 5%

![]() Type:Polar piece folding, breakage, leakage, edge sealing foreign body,convex, pinhole......

Type:Polar piece folding, breakage, leakage, edge sealing foreign body,convex, pinhole......

-

master map

-

result