2.5D / 3D Phone Cover Glass

Surface detection

![]() Speed:≤ 2.3s/pc

Speed:≤ 2.3s/pc

![]() Result:Loss ≤ 2.5% | Fault ≤ 10%

Result:Loss ≤ 2.5% | Fault ≤ 10%

![]() Type:Smudge, hair, dust spot, scratch, edge collapse, bump, deep scratch......

Type:Smudge, hair, dust spot, scratch, edge collapse, bump, deep scratch......

-

master map

-

result

Metallized Ceramics

Surface detection

![]() Speed:≤ 100ms/pc

Speed:≤ 100ms/pc

![]() Result:Loss ≤ 0.3% | Fault ≤ 1%

Result:Loss ≤ 0.3% | Fault ≤ 1%

![]() Type:Scratches, chipped edges, smudges, cracks, scratches, missing......

Type:Scratches, chipped edges, smudges, cracks, scratches, missing......

-

master map

-

result

Metallic Part

Surface detection

![]() Speed:≤ 500ms/pc

Speed:≤ 500ms/pc

![]() Result:Loss ≤ 0.1% | Fault ≤ 5%

Result:Loss ≤ 0.1% | Fault ≤ 5%

![]() Type:Smudge, bright mark, scratch, spot, mold, knife grain, notch......

Type:Smudge, bright mark, scratch, spot, mold, knife grain, notch......

-

master map

-

result

Steel plate detection

Surface detection

![]() Speed:≥120pcs/min

Speed:≥120pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 5%

Result:Loss ≤ 0.1% | Fault ≤ 5%

![]() Type:Burr, scratch, bruise......

Type:Burr, scratch, bruise......

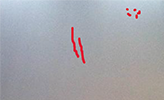

-

master map

-

result

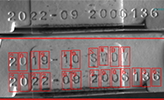

Industrial character recognition

Surface detection

![]() Speed:≤ 120ms/pc

Speed:≤ 120ms/pc

![]() Result:Precision rate ≥ 99.99%

Result:Precision rate ≥ 99.99%

-

master map

-

result

The finished jelly

Surface detection

![]() Speed:≥100pcs/min

Speed:≥100pcs/min

![]() Result:Loss ≤ 0.2% | Fault ≤ 5%

Result:Loss ≤ 0.2% | Fault ≤ 5%

![]() Type:Hair, pulp insects, black residue, air bubbles, iron filings......

Type:Hair, pulp insects, black residue, air bubbles, iron filings......

-

master map

-

result

Face detection

Surface detection

![]() Speed:≥235pcs/min

Speed:≥235pcs/min

![]() Result:Loss ≤ 1% | Fault ≤ 1%

Result:Loss ≤ 1% | Fault ≤ 1%

![]() Type:Singe, foreign body, hair, dirty......

Type:Singe, foreign body, hair, dirty......

-

master map

-

result

Medicine plate detection

Surface detection

![]() Speed:≥500pcs/min

Speed:≥500pcs/min

![]() Result:Loss ≤ 0.001% | Fault ≤ 0.001%

Result:Loss ≤ 0.001% | Fault ≤ 0.001%

![]() Type:Deformation、foreign body、line error、blow-by......

Type:Deformation、foreign body、line error、blow-by......

-

master map

-

result

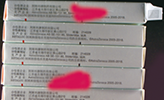

Medicine boxes

Surface detection

![]() Speed:≥500pcs/min

Speed:≥500pcs/min

![]() Result:Loss ≤ 0.001% | Fault ≤ 0.001%

Result:Loss ≤ 0.001% | Fault ≤ 0.001%

![]() Type:Damaged,smudged,medicine box opening,deformation,label curling......

Type:Damaged,smudged,medicine box opening,deformation,label curling......

-

master map

-

result

OCR test of medicine plate and box

Surface detection

![]() Speed:≥500pcs/min

Speed:≥500pcs/min

![]() Result:Precision rate ≥ 99.99%

Result:Precision rate ≥ 99.99%

-

master map

-

result

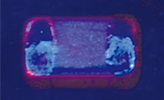

Electronic Components

Surface detection

![]() Speed:≤ 2ms/pc

Speed:≤ 2ms/pc

![]() Result:Loss ≤ 0.01% | Fault ≤ 1%

Result:Loss ≤ 0.01% | Fault ≤ 1%

![]() Type:Magnetic leakage,bubbles,cracking,deformation,black,crack,crescent,trachoma,indentation......

Type:Magnetic leakage,bubbles,cracking,deformation,black,crack,crescent,trachoma,indentation......

-

master map

-

result

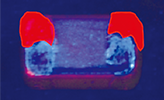

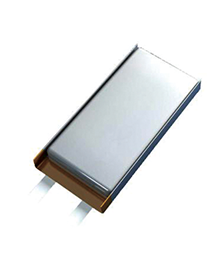

Pouch power cell

Surface detection

![]() Speed:≤ 5s/pc

Speed:≤ 5s/pc

![]() Result:Loss ≤ 0.1%(serious defects is 0) | Fault ≤ 5%

Result:Loss ≤ 0.1%(serious defects is 0) | Fault ≤ 5%

![]() Type:Polar piece folding, breakage, leakage, edge sealing foreign body,convex, pinhole......

Type:Polar piece folding, breakage, leakage, edge sealing foreign body,convex, pinhole......

-

master map

-

result

Wet magnetic tile

Surface detection

![]() Speed:≥80pcs/min

Speed:≥80pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 15%

Result:Loss ≤ 0.1% | Fault ≤ 15%

![]() Type:Crack, collapse, air hole, bad grinding, bad chamfering......

Type:Crack, collapse, air hole, bad grinding, bad chamfering......

-

master map

-

result

Dry magnetic tile

Surface detection

![]() Speed:≥120pcs/min

Speed:≥120pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 10%

Result:Loss ≤ 0.1% | Fault ≤ 10%

![]() Type:Crack, collapse, trachoma......

Type:Crack, collapse, trachoma......

-

master map

-

result

Ferrite bead

Surface detection

![]() Speed:≥120pcs/min

Speed:≥120pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 10%

Result:Loss ≤ 0.1% | Fault ≤ 10%

![]() Type:Crack, collapse, plug hole, burr......

Type:Crack, collapse, plug hole, burr......

-

master map

-

result

Sintered magnet

Surface detection

![]() Speed:≥100pcs/min

Speed:≥100pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 10%

Result:Loss ≤ 0.1% | Fault ≤ 10%

![]() Type:Crack, corner drop, pitting, knife mark, hole, inclusions, corrosion.....

Type:Crack, corner drop, pitting, knife mark, hole, inclusions, corrosion.....

-

master map

-

result

Soft magnetic core

Surface detection

![]() Speed:≥200pcs/min

Speed:≥200pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 10%

Result:Loss ≤ 0.1% | Fault ≤ 10%

![]() Type:Crack, corner drop, speckle, mucous membrane, slurry, abrasion......

Type:Crack, corner drop, speckle, mucous membrane, slurry, abrasion......

-

master map

-

result

Bonded magnetic ring

Surface detection

![]() Speed:≥100pcs/min

Speed:≥100pcs/min

![]() Result:Loss ≤ 0.05% | Fault ≤ 10%

Result:Loss ≤ 0.05% | Fault ≤ 10%

![]() Type:Cracks, defects, pitting, magnetic flux leakage, pits, foreign bodies......

Type:Cracks, defects, pitting, magnetic flux leakage, pits, foreign bodies......

-

master map

-

result

How many image data need to be learned for each defect category?

How many image data need to be learned for each defect category?

The number of images to be learned will vary according to the complexity of the images, but in the initial stage, about 40-100 images for different defect categories can be provided。

The number of images to be learned will vary according to the complexity of the images, but in the initial stage, about 40-100 images for different defect categories can be provided。

How long does it take to build the neural network model?

How long does it take to build the neural network model?

The general image size of 2048*2048 pixels, 500 for the standard, about 30 minutes。

The general image size of 2048*2048 pixels, 500 for the standard, about 30 minutes。

Industrial AI vision kit installation, need to change production line?

Industrial AI vision kit installation, need to change production line?

Can be directly installed to the original production line, generally do not need to extend the additional major production line。

Can be directly installed to the original production line, generally do not need to extend the additional major production line。

What is the recognition speed that can be achieved in the actual production line?

What is the recognition speed that can be achieved in the actual production line?

For example, the inspection project of medicine box packaging can detect about 500 products in a minute through full inspection,the specific situation of each project is different, so please take the actual project situation as the criterion。

For example, the inspection project of medicine box packaging can detect about 500 products in a minute through full inspection,the specific situation of each project is different, so please take the actual project situation as the criterion。

Can multiple different defects be identified?Is there an upper limit on the number of identifications?

Can multiple different defects be identified?Is there an upper limit on the number of identifications?

Supports multiple different categories of defects in the same project, with no upper limit on the number of categories detected。

Supports multiple different categories of defects in the same project, with no upper limit on the number of categories detected。

Whether the software is a standardized product?

Whether the software is a standardized product?

Products are standardized, with a strong versatility.At the same time, according to the special needs of users in different industries, technical personnel can customize the program according to the needs on the basis of the product。

Products are standardized, with a strong versatility.At the same time, according to the special needs of users in different industries, technical personnel can customize the program according to the needs on the basis of the product。

Is the image sample formatted?

Is the image sample formatted?

Image format is not limited, basically covering all image formats.Such as JPEG, BMP, PNG and so on。

Image format is not limited, basically covering all image formats.Such as JPEG, BMP, PNG and so on。