-

-

Mobile phone manufacturing

-

-

It is difficult for the naked eye to distinguish scratches, chipping, dirt and other defects appear on the surface of transparent glass, and the high-definition imaging manual detection efficiency is low. But through GalileoX detection can identify precisely in milliseconds, classify and list all defects, it can calculate defect length, width, area, defect level, defect score, etc. and adjust freely defect pass rate.

-

It will carry out stereo inspection for whether the components are installed properly, whether the installation is in place, etc., when the products are assembled. Relevant data is connected to the hardware and the unqualified products are classified to further improve the production quality of the enterprise.

-

Precise component inspection, detect product defects in small nuances, ultra-precise and more efficient in automatic detection and recognition for the entire process of each part of the product.

-

-

Printing manufacturing

-

GalileoX provides perfect and complete process accurate inspection for printing and packing enterprises. Whether the product is packaged by paper, plastic, metal or special materials, it can inspect intact of the packing, and whether it is intact and the position is accurate etc. for the color, text, barcode, date etc. It can also accurately identify the products QR Code, validate the security code uniqueness, detect the layer integrity.

-

-

Tobacco manufacturing

-

The classification of tobacco quality grades has high recognition accuracy, which greatly improves the classification efficiency. In the face of quite complex object recognition, GalileoX has achieved amazing results and solved many problems in the classification of tobacco industry.

-

-

Building materials manufacturing

-

Inspection for building materials floor, tile surface, sheet compression structure, sheet paint, engraving texture , fabric texture, etc.

-

-

Food production

-

It is widely used in the whole inspection process of fruit and vegetable production and packing, drinking production and packing, food production and packing. Such as food safety inspection, multiple inspections for internal, surface impurities, defects, etc before being packed and re-inspections for package internal , packing, external surface after being packed.

-

-

Intelligent monitoring

-

Face detection and feature tracking technology It detects and locates the driver's face, tracks his head movement, and detects the positioning of facial features, such as eyes and mouth, tracking its movements, and judging whether the driver is tired of driving and attention shift. |

Passenger flow statistical video analysis technology From the camera image, accurate detect everyone in real-time, each person's walking direction, carry out accurate statistics of the number of people entering and leaving in different light, weather and other environments. |

-

-

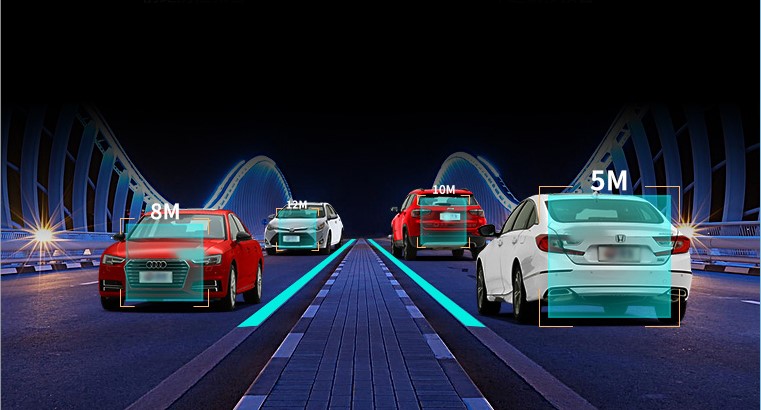

Intelligent driving

-

Dangerous driving behavior detection technology Visually analyze and classify the camera image to automatically determine whether the current driving behavior is safe. |

Lane offset and pavement detection technology The lane is detected accurately from the camera image in real time, and the lane offset is predicted. Also check if the road surface is abnormal. |

-

-

Others

-

Garbage sorting robots, GalileoX can provide a more intelligent robotic visual nervous system, enhance the visual recognition function of garbage sorting robots, and classify more efficiently and accurately. |

Surface defect detection of flexible objects. |